Opinion & Analysis

From idea to reality: Golf club design at major OEMs

Like nearly every modern project of sophisticated design, the club creation process begins with computer-aided design (CAD) software. Ping, an Arizona-based equipment company, primarily drafts using a product design suite called Creo, according to VP of Engineering Paul Wood, although there are several software options that do essentially the same thing.

The ultimate objective in the early design stages, according to Wood? “Essentially using the tools as a sketchbook.”

Everyone on the Ping team is adept using Creo, so moving to another platform would “be like starting over again.” Cleveland golf, for its part, uses Altair’s suite of design applications.

So that G30 in you hand? It began as a digital sketch on Wood’s team’s computer screens.

Wood, who holds a PhD in Applied Mathematics from the University of St. Andrews, said Ping uses different software for different aspects of the design process. Alternatively, specialists have particular preferences, which may not speak to the inherent merits of one software over another, but rather to what a particular person doing a particular job is comfortable with.

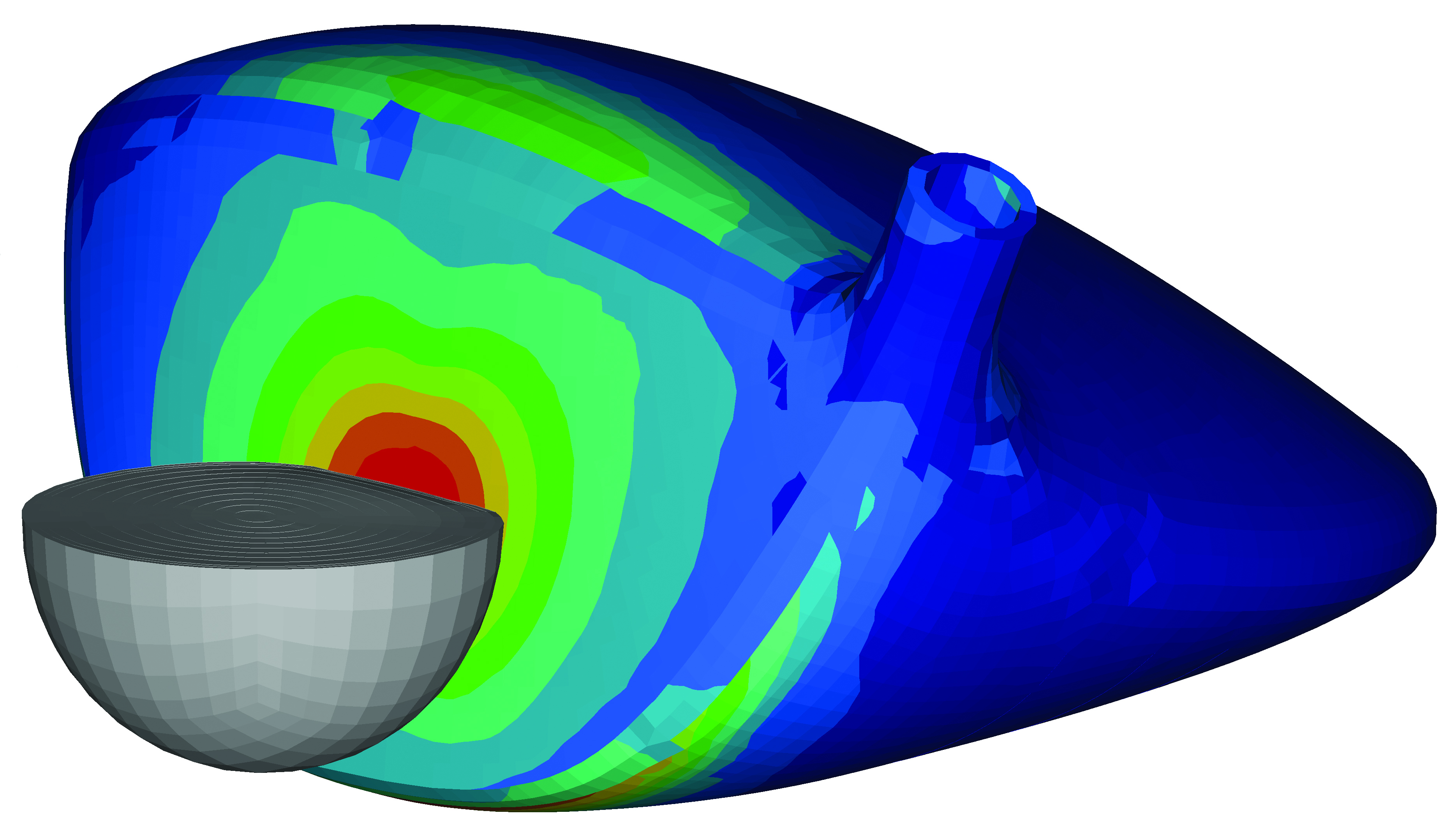

[quote_box_center]”We use some Altair stuff to do our finite element analysis: taking a model … a driver head or whatever, simulating impact, looking at where the stress and strains are … predictions of performance … We have a guy that’s full time,” Wood said. “He’ll work with the design team and pull the design from CREO. We also have aerodynamics packages that will simulate airflow, which is another specialist role.”[/quote_box_center]

I asked Dustin Brekke, Engineering Manager, Research and Development for Cleveland, how the company uses the same Altair software. He said the ultimate objective with the software use is “to evaluate, eliminate, and improve designs prior to spending the time and money to make samples.” The process of evaluating design concepts is different for each club. For woods, the company is assessing the strength of materials and face thickness and simulating impact conditions.

So, regardless of the particular software and its specific applications, the objective is the same: model initial concepts in CAD software and test them prior to production.

How CAD software was a game changer

Todd Beach, VP Product Development, TaylorMade Golf Company, laid out the differences between the pre-1990s method of club design and CAD-based design.

Before the 1990s, Beach said, clubmakers hand-shaped master designs “based on external cosmetics.” Companies would then use the masters to make the tools for the casting process. Adjustments and improvements would then be made.

[quote_box_center]

“Now clubs are designed with high powered CAD systems, which model all of the complex internal features and adjustability features,” Beach said. “The mass properties can be optimized on the computer before ever launching a prototype.

“The sound/feel, durability, aerodynamics and launch performance can also be simulated using sophisticated finite element methods [virtual prototyping]. Using these tools, it is possible to iterate multiple times to optimize performance before launching the first test prototype.”

[/quote_box_center]

Cleveland’s Brekke highlighted the speed of the CAD-based design process. In the case of creating a “master” design prior to CAD software, not only was the process significantly more time consuming, a company was left with just one design to test, rather than multiple variations.

[quote_box_center]”That is how the industry has changed so much in the last few decades,” Brekke said. “With all the advances in modeling, simulation, and rapid prototyping exponentially more design concepts can be evaluated and therefore new discoveries are constantly within reach.”[/quote_box_center]

So from process, innovation, and speed-to-market standpoints, CAD suites like Creo and Altair have changed the game.

Working outside the product cycle

There are two modes of operation in the engineering world of major OEMs: inside and outside the product cycle. The companies try to do as much as they can outside of the product cycle, which isn’t surprising, given the innovation imperative in golf equipment and the need to produce game-improving, marketable products.

Rather than thinking about next year’s driver or specific clubs, outside the product cycle, the engineers are more concerned with concepts and technologies. As Wood says, outside the product cycle, “we try to do things generally,” saying, “this would apply to any driver,” rather than worrying about specific constraints or what was on the shelf last year.

However, at Ping at least, there’s a team that is perpetually working outside of specific product cycles whose only imperative is innovation.

[quote_box_center]”We have a dedicated innovation team that is much more outside of the specific product cycle, aiming at technology development, knowledge development, things that the design team can kind of plug into the next club they have.”[/quote_box_center]

The end goal, of course, is a market-beating offering. However, to deliver, say, the next great driver, said driver needs to be loaded with innovative components. It’s to this end that Wood says, “we want to know as much as we can about technology and materials and the specifics of what’s going on and what the customer needs.”

TaylorMade’s Todd Beach echoed Wood’s sentiments about the market and customer needs as well as the ongoing pursuit of innovation.

[quote_box_center]“We have several teams working on … concepts, which are more breakthrough, next-generation stuff. Stuff where you don’t know if it’s going to work, so you don’t have a specific time frame on it. And our product marketing group is constantly looking at the marketplace and seeing what products are resonating in the marketplace.”[/quote_box_center]

Interestingly, Beach added, R&D may continue to work on a concept for a long time, even in excess of 10 years if the marketing team feels a technology is truly groundbreaking.

Within the product cycle

Inside the product cycle, as you’d expect, things are more systematized, coordinated and deadline driven.

How long is the product cycle? Anywhere from one year to three years.

And rather than seeking to reinvent the wheel, companies often begin with the most recent design for, say a driver, and seek to improve upon it/implement technologies they’ve been working on.

[quote_box_center]“You’re taking ideas you might want to incorporate into the next model,” Wood said. “So for some of that, you can take an existing prototype … For example, we can take the G30 iron and mess around with it.”[/quote_box_center]

After the club in question has been sufficiently “messed around with” to create something worth investigating further, the company will produce a few prototypes for initial testing.

Alternatively, as Wood indicated, designers may want to build a few prototypes merely to test a new technology to arrive at a point called “concept validation,” which determines the viability of a technology for inclusion in a future club offering.

Beach said TaylorMade often begins a product cycle with the question: “What’s the best fit given the technologies the Phase I group has been working on?”

Beyond messing around to see what works and prototype creation, the rubber meets the road once a company enters into product development and firmer decisions must be made.

[quote_box_center]“Once you start to get into product development … we’ll start to make decisions like ‘this is going to be a cast iron,’” Wood says. “You start worrying about every little detail and that’s when maybe you’d start working with a supplier.”[/quote_box_center]

And an interesting note about product development, particularly iron development. Ping will often start with a 7-iron then build backward (6, 5, 4) and forward (8, 9) until they have a whole set, tweaking the initial 7-iron design. Likewise, driver design often begins with the 9-degree, right-handed model.

A component of club production, of course, is tool creation. For example, producing the metal blocks used in the iron casting process. And a big part of scaling up production is getting overseas manufacturers the appropriate tools with the appropriate tolerances to create quality products.

During this time, TaylorMade moves between durability, player and consumer testing as a lead-up to mass production.

Following these preliminaries, a company will usually initiate a pilot run to work out the details of production, costs (including scrap rates) and tolerances. At this point, a U.S.-based club company can authorize its overseas production facility to manufacture a run of five of 10,000 units.

Assuming the above goes off without a hitch, “ownership” of the project transfers from the design team to what Wood referred to as the “quality group.”

“Once you’ve gone through the pilot and have done all the tweaking and adjusting specs, it’s now a quality function … On our supplier’s end, it’s gone from product development to factory floor production … What they’re doing is developing these very detailed work instructions, which we help with … But it’s now a factory procedure … it’s the same thing if you’re Intel making chips.”

Likewise, Beach said that at this point in production, “It’s probably not that much different than other technical products.”

So that, in a nutshell, is how a team of designers in Carlsbad or Phoenix created the M1 or G30 that’s in your bag.

Opinion & Analysis

The 2 primary challenges golf equipment companies face

As the editor-in-chief of this website and an observer of the GolfWRX forums and other online golf equipment discourse for over a decade, I’m pretty well attuned to the grunts and grumbles of a significant portion of the golf equipment purchasing spectrum. And before you accuse me of lording above all in some digital ivory tower, I’d like to offer that I worked at golf courses (public and private) for years prior to picking up my pen, so I’m well-versed in the non-degenerate golf equipment consumers out there. I touched (green)grass (retail)!

Complaints about the ills of and related to the OEMs usually follow some version of: Product cycles are too short for real innovation, tour equipment isn’t the same as retail (which is largely not true, by the way), too much is invested in marketing and not enough in R&D, top staffer X hasn’t even put the new driver in play, so it’s obviously not superior to the previous generation, prices are too high, and on and on.

Without digging into the merits of any of these claims, which I believe are mostly red herrings, I’d like to bring into view of our rangefinder what I believe to be the two primary difficulties golf equipment companies face.

One: As Terry Koehler, back when he was the CEO of Ben Hogan, told me at the time of the Ft Worth irons launch, if you can’t regularly hit the golf ball in a coin-sized area in the middle of the face, there’s not a ton that iron technology can do for you. Now, this is less true now with respect to irons than when he said it, and is less and less true by degrees as the clubs get larger (utilities, fairways, hybrids, drivers), but there remains a great deal of golf equipment truth in that statement. Think about it — which is to say, in TL;DR fashion, get lessons from a qualified instructor who will teach you about the fundamentals of repeatable impact and how the golf swing works, not just offer band-aid fixes. If you can’t repeatably deliver the golf club to the golf ball in something resembling the manner it was designed for, how can you expect to be getting the most out of the club — put another way, the maximum value from your investment?

Similarly, game improvement equipment can only improve your game if you game it. In other words, get fit for the clubs you ought to be playing rather than filling the bag with the ones you wish you could hit or used to be able to hit. Of course, don’t do this if you don’t care about performance and just want to hit a forged blade while playing off an 18 handicap. That’s absolutely fine. There were plenty of members in clubs back in the day playing Hogan Apex or Mizuno MP-32 irons who had no business doing so from a ballstriking standpoint, but they enjoyed their look, feel, and complementary qualities to their Gatsby hats and cashmere sweaters. Do what brings you a measure of joy in this maddening game.

Now, the second issue. This is not a plea for non-conforming equipment; rather, it is a statement of fact. USGA/R&A limits on every facet of golf equipment are detrimental to golf equipment manufacturers. Sure, you know this, but do you think about it as it applies to almost every element of equipment? A 500cc driver would be inherently more forgiving than a 460cc, as one with a COR measurement in excess of 0.83. 50-inch shafts. Box grooves. And on and on.

Would fewer regulations be objectively bad for the game? Would this erode its soul? Fortunately, that’s beside the point of this exercise, which is merely to point out the facts. The fact, in this case, is that equipment restrictions and regulations are the slaughterbench of an abundance of innovation in the golf equipment space. Is this for the best? Well, now I’ve asked the question twice and might as well give a partial response, I guess my answer to that would be, “It depends on what type of golf you’re playing and who you’re playing it with.”

For my part, I don’t mind embarrassing myself with vintage blades and persimmons chasing after the quasi-spiritual elevation of a well-struck shot, but that’s just me. Plenty of folks don’t give a damn if their grooves are conforming. Plenty of folks think the folks in Liberty Corner ought to add a prison to the museum for such offences. And those are just a few of the considerations for the amateur game — which doesn’t get inside the gallery ropes of the pro game…

Different strokes in the game of golf, in my humble opinion.

Anyway, I believe equipment company engineers are genuinely trying to build better equipment year over year. The marketing departments are trying to find ways to make this equipment appeal to the broadest segment of the golf market possible. All of this against (1) the backdrop of — at least for now — firm product cycles. And golfers who, with their ~15 average handicap (men), for the most part, are not striping the golf ball like Tiger in his prime and seem to have less and less time year over year to practice and improve. (2) Regulations that massively restrict what they’re able to do…

That’s the landscape as I see it and the real headwinds for golf equipment companies. No doubt, there’s more I haven’t considered, but I think the previous is a better — and better faith — point of departure when formulating any serious commentary on the golf equipment world than some of the more cynical and conspiratorial takes I hear.

Agree? Disagree? Think I’m worthy of an Adam Hadwin-esque security guard tackle? Let me know in the comments.

@golfoncbs The infamous Adam Hadwin tackle ? #golf #fyp #canada #pgatour #adamhadwin ? Ghibli-style nostalgic waltz – MaSssuguMusic

Podcasts

Fore Love of Golf: Introducing a new club concept

Episode #16 brings us Cliff McKinney. Cliff is the founder of Old Charlie Golf Club, a new club, and concept, to be built in the Florida panhandle. The model is quite interesting and aims to make great, private golf more affordable. We hope you enjoy the show!

Opinion & Analysis

On Scottie Scheffler wondering ‘What’s the point of winning?’

Last week, I came across a reel from BBC Sport on Instagram featuring Scottie Scheffler speaking to the media ahead of The Open at Royal Portrush. In it, he shared that he often wonders what the point is of wanting to win tournaments so badly — especially when he knows, deep down, that it doesn’t lead to a truly fulfilling life.

View this post on Instagram

“Is it great to be able to win tournaments and to accomplish the things I have in the game of golf? Yeah, it brings tears to my eyes just to think about it because I’ve literally worked my entire life to be good at this sport,” Scheffler said. “To have that kind of sense of accomplishment, I think, is a pretty cool feeling. To get to live out your dreams is very special, but at the end of the day, I’m not out here to inspire the next generation of golfers. I’m not out here to inspire someone to be the best player in the world, because what’s the point?”

Ironically — or perhaps perfectly — he went on to win the claret jug.

That question — what’s the point of winning? — cuts straight to the heart of the human journey.

As someone who’s spent over two decades in the trenches of professional golf, and in deep study of the mental, emotional, and spiritual dimensions of the game, I see Scottie’s inner conflict as a sign of soul evolution in motion.

I came to golf late. I wasn’t a junior standout or college All-American. At 27, I left a steady corporate job to see if I could be on the PGA Tour starting as a 14-handicap, average-length hitter. Over the years, my journey has been defined less by trophies and more by the relentless effort to navigate the deeply inequitable and gated system of professional golf — an effort that ultimately turned inward and helped me evolve as both a golfer and a person.

One perspective that helped me make sense of this inner dissonance around competition and our culture’s tendency to overvalue winning is the idea of soul evolution.

The University of Virginia’s Division of Perceptual Studies has done extensive research on reincarnation, and Netflix’s Surviving Death (Episode 6) explores the topic, too. Whether you take it literally or metaphorically, the idea that we’re on a long arc of growth — from beginner to sage elder — offers a profound perspective.

If you accept the premise literally, then terms like “young soul” and “old soul” start to hold meaning. However, even if we set the word “soul” aside, it’s easy to see that different levels of life experience produce different worldviews.

Newer souls — or people in earlier stages of their development — may be curious and kind but still lack discernment or depth. There is a naivety, and they don’t yet question as deeply, tending to see things in black and white, partly because certainty feels safer than confronting the unknown.

As we gain more experience, we begin to experiment. We test limits. We chase extreme external goals — sometimes at the expense of health, relationships, or inner peace — still operating from hunger, ambition, and the fragility of the ego.

It’s a necessary stage, but often a turbulent and unfulfilling one.

David Duval fell off the map after reaching World No. 1. Bubba Watson had his own “Is this it?” moment with his caddie, Ted Scott, after winning the Masters.

In Aaron Rodgers: Enigma, reflecting on his 2011 Super Bowl win, Rodgers said:

“Now I’ve accomplished the only thing that I really, really wanted to do in my life. Now what? I was like, ‘Did I aim at the wrong thing? Did I spend too much time thinking about stuff that ultimately doesn’t give you true happiness?’”

Jim Carrey once said, “I think everybody should get rich and famous and do everything they ever dreamed of so they can see that it’s not the answer.”

Eventually, though, something shifts.

We begin to see in shades of gray. Winning, dominating, accumulating—these pursuits lose their shine. The rewards feel more fleeting. Living in a constant state of fight-or-flight makes us feel alive, yes, but not happy and joyful.

Compassion begins to replace ambition. Love, presence, and gratitude become more fulfilling than status, profits, or trophies. We crave balance over burnout. Collaboration over competition. Meaning over metrics.

Interestingly, if we zoom out, we can apply this same model to nations and cultures. Countries, like people, have a collective “soul stage” made up of the individuals within them.

Take the United States, for example. I’d place it as a mid-level soul: highly competitive and deeply driven, but still learning emotional maturity. Still uncomfortable with nuance. Still believing that more is always better. Despite its global wins, the U.S. currently ranks just 23rd in happiness (as of 2025). You might liken it to a gifted teenager—bold, eager, and ambitious, but angsty and still figuring out how to live well and in balance. As much as a parent wants to protect their child, sometimes the child has to make their own mistakes to truly grow.

So when Scottie Scheffler wonders what the point of winning is, I don’t see someone losing strength.

I see someone evolving.

He’s beginning to look beyond the leaderboard. Beyond metrics of success that carry a lower vibration. And yet, in a poetic twist, Scheffler did go on to win The Open. But that only reinforces the point: even at the pinnacle, the question remains. And if more of us in the golf and sports world — and in U.S. culture at large — started asking similar questions, we might discover that the more meaningful trophy isn’t about accumulating or beating others at all costs.

It’s about awakening and evolving to something more than winning could ever promise.

Sean

Oct 26, 2015 at 8:25 pm

Enjoyed the article. Constantly tweaking current model for the next model. That makes sense, however, I would think they need some kind of “out of the box” ideas as well. 🙂

TR1PTIK

Oct 26, 2015 at 3:45 pm

Though I have no experience with it (or even a real desire to learn it), I’ve always been fascinated with CAD. It’s amazing how much can be done with a computer these days. Tom, aside from the time spent on the design and production of new clubs you have to also consider all of the costs associated with CAD software, tooling, and R&D among many other things. I’m not thrilled with the current prices for a new set of clubs, but I fully understand the reasoning for those prices as someone who works in manufacturing and technology.

Really good read Ben.

Tom

Oct 26, 2015 at 3:30 pm

“Interestingly, Beach added, R&D may continue to work on a concept for a long time, even in excess of 10 years if the marketing team feels a technology is truly groundbreaking.” Well that blows my criticism of this technology saving time and money for companies and yet cost to consumers remains at an all time high.

Tom Wishon

Oct 29, 2015 at 1:52 pm

LOL!!! How well you pointed that out. I guess in a sense it is a different type of oxymoron to say that they use CAD to instantly create different iterations for analysis yet they take pride in saying that they spend several years before it goes to market.

Having started in clubhead design in 1986 when it was only done by machining master models from which the dies and molds were cut by EDM off the master, it’s really been interesting for me to evolve my own head design methods from all “dinosaur” to a combination of dinosaur and modern so I can still be comfortable with it. I still love to hand make my own master models of new designs and couple that with 2D old school drawings – call it a sense of pride in the hand skills and the fact that I have always designed a lot with my eyes for the look of a head in various ways.

But then of course these days I then have a CAD operator take my models and drawings and create 3d models for me to approve plus the CAD file so the die/mold production can be done more easily. And depending the model, FEA is very nice as a means to predict performance. But in the end nothing passes for me until people hit it and a robot offers what it can offer to help verify performance.

At the same time, not saying this to blow any horn whatsoever, but in any of the many technology firsts I was privileged to contribute to head design in my career, not one of them took longer than 8 months from start to finish to do and to get right. So when I read this 2-3 yrs in development, I see that as a big company with too many people having some part of the say so over what the company brings to market such that it just slows things down.

other paul

Oct 26, 2015 at 1:56 pm

I thought that was interesting.

redneckrooster

Oct 26, 2015 at 10:13 am

SOOO THERE IS NOTHING BETTER TO DO WITH OUR TIME ?

Michael

Oct 26, 2015 at 12:29 pm

Well you clearly have better things to do.

Easy on the caps lock, bro.

MARCUS

Oct 26, 2015 at 1:43 pm

Helped pass my time here at work. 10 hr work days seem to draq without something good to read.

Trab

Oct 27, 2015 at 2:39 am

How about actually doing work? You Eejit, Marcus