Opinion & Analysis

Building Golf Clubs at Home: The Essential Tips, Tricks and Tools

Like so many others I got into club building out of necessity and curiosity. As a kid, I loved to take anything and everything apart — from skateboards to old lawnmowers — so when I starting playing golf clubs were next. It started small, learning how to grip clubs with a Black & Decker workmate with my dad, and then slowly I moved into the more intricate aspects of building clubs. I’ve always joked that I was probably the only 16-year-old who asked for a lie-loft machine for his birthday.

In this article, I’m going to share with you my favorite tips, tricks and tools that I’ve used as a professional golf club builder. I hope to benefit those interested in building their own golf clubs at home, as well as relay valuable information about club building in general to knowledge-hungry GolfWRXers.

Overview

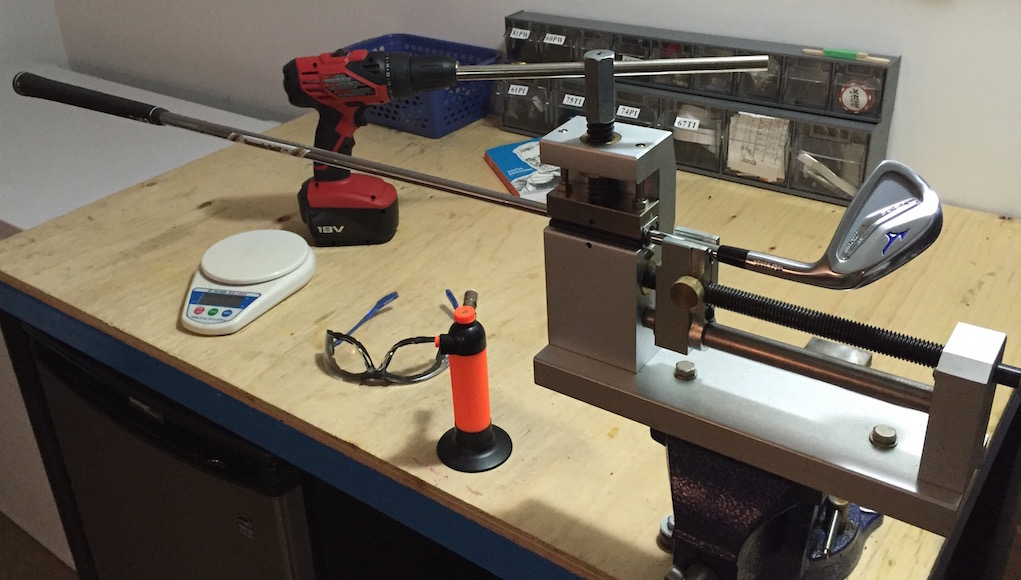

One of the most important things about building clubs is doing it properly with the right tools, and doing it safely. After setting up up multiple build shops over the years, from small hobby shops to large multi-station build shops, having the opportunity to build my own home shop from the ground up was something I always looked forward to. My shop is in my basement, and because of the limited space, it was imperative to find as many space saving-solutions as possible.

Like many people with a hobby they are passionate about, I look forward to one day having a stand-alone garage for all of my tools (and maybe a hitting net), but for now my basement gets the job done. I’m lucky to have access to a much large machine shop where I do wedge grinding, finishing and sand blasting, which are all jobs that make a lot more noise and create a lot more dust. I can’t get away with doing those things in a confined space, but we’ll touch on that later.

Although not a tool, arguably the most important piece of equipment is the work bench. Having a quality workbench is needed because of the amount of abuse that it will take over its lifespan. Also, just like a great kitchen design, you need counter space and a good workbench provides that. Dropping a clubhead (especially a driver or fairway wood with nice paint job) can be costly. The next extension of the workbench is a good vice that has been properly attached to the bench with bolts. Like I’ve said in previous articles, I believe when you do something you should take the time to do it properly. I once saw a vice screwed into a workbench with 1.25-inch screws, and as soon as someone went to use the vice it ripped out and took a club with it.

Not every surface needs to be as stable as a full-scale industrial workbench, but having counter space is important. My personal solution to this was IKEA (honestly, who doesn’t love IKEA?). I recommend checking out Ikea Hacks (just Google it) for space-saving tips. If your space is really limited or needs to be multi-use, flip-up table ends are a perfect solution. As much as I like finding quick solutions to problems, it’s way more satisfying to build things yourself if possible. That way, at the end of the project, you have something that is exactly the way you wanted it.

As seen in the pictures below, I re-purposed two Ikea BEKAN desk bases from the As-Is section into a full workbench after getting a 4-foot by 8-foot piece of 0.75-inch plywood cut to size. This saved me hundreds of dollars and got me close to 30 square feet of counter space to mount other tools including my bench ruler, chop saw, belt sander and frequency machine. And since these desk bases have adjustable heights, I was able to get them to a comfortable workbench height.

There are lots of kits available online to build benches to fit almost any space. Get creative, and customize it to your needs.

One of the other things that’s very important is organization. Having a few small organizational tools can make a difference: think storage bins, trays and component drawers, which are especially useful for ferrules and tip weights. Make sure to put labels on them, too, so it’s always easy to find what you need.

The Tools

Unlike a golf bag where you are limited to 14 clubs, your build shop is only limited to the amount of space you have (and your budget). For me, every trip to the hardware store or to various tool supply shops has me finding another small tool or bit to help make things just a bit easier. Let’s put it this way; I have a lot of LED flashlights and finishing tools lying around.

What I’m trying to say is that what you should really focus on when building a shop from the ground up is quality over quantity. Having the proper tools will make building clubs and doing repairs a lot easier. There are very few things as frustrating as having a club not turn out the way you wanted because you weren’t prepared and didn’t have the right tools for the job.

Cordless Drill

A good cordless drill is a necessity, so make a quality purchase. I’m not an expert on drills, but any of the big name-brand drills that use an 18-20V battery have always done well for me. Make sure the drill has variable torque settings and, if possible, having one that has a built-in flashlight under the chuck makes it super easy to check hosels for debris while drilling. It’s also more ideal to find one in a kit that has two batteries with the charger — that way, if you’re drilling a lot for a single job, you will always have a fresh battery. You should expect to pay $119-$200.

I have seen many shops use a drill press, but personally I never found a real need for one on a day-to-day basis (plus they can take up a bunch of space). Drill presses can be useful for porting wedges, but that’s really not home-shop use.

Metal Drill Bits

Here’s where things get personal for me. I had an inexpensive drill bit break almost instantly and go right into the palm of my left hand (and off to the ER I went). I was not a happy camper, but I did learn a very valuable lesson; don’t buy cheap drill bits and never drill toward another body part. I still have a small scar to remind me of that mistake, and it also serves as a reminder to never take what you may consider a simple repair for granted. Bit sets can often be found on sale, but a small collection of proper bits will run you about $100.

Also, make sure to purchase proper metal drill bits. I’ve lost count of how many times I’ve seen people try and use either masonry or wood drill bits with little success.

Chop Saw

A good chop saw is worth every penny. There’s nothing worse than using a crappy saw and having it splinter the butt section of an expensive driver shaft. My personal favorite, and the favorite of many professionals, is the Gryphon Miter Saw. Almost any video in a tour van features one of these saws… and for good reason. They are compact, durable, use relatively inexpensive blades,and also make very precise cuts at high RPM. The better the blades and higher the RPM, the better the cut.

I don’t do that much volume in my basement, so I went with a more basic chop saw from GolfWorks that uses 6-inch blades. I did my research. It is still a good quality saw and worked with my budget, but compared to the Gryphon that I used in the past it is louder. The Gryphon is $260 direct from Gryphon, while mine was in the $80 range from GolfWorks. I’ve had my saw from almost eight years, and although is doesn’t see anything close to an industrial workload it performs great.

Side Note: Just like with drill bits, be sure to buy quality cutting wheels made for steel and other fibers. The thinner the better, because they will help keep dust down and reduce noise.

Belt Sander

Who doesn’t love the look of a properly turned-down ferrule that has just been shined with acetone? To me, this is one of the most important aspects of finishing a club. It seems simple, but it took me a long time to get really good at it.

To properly turn down a ferrule you need a belt sander, and don’t skimp on a cheap one. The best ones use 42-inch belts, and I prefer the DuraBrite Felt belts since they don’t take too much material off the ferrule at once. This makes them more forgiving, especially for beginners, and I find them much cleaner, which makes final finishing easier. You can use a belt sander with a inexpensive motor for around or under $100, but you can’t go cheap on the attachments. The attachment shown here is the most widely used and reliable one that I’ve found and costs around $200 from most suppliers. Some of the most reliable tools found in shops have Baldor Motors that alone start around $350. Since grinders are very common tools, you can often get a good deal on a used one if you stay patient.

Dust Collector

You can’t cut or sand at any volume without creating dust. I don’t know what the long-term effects of breathing in graphite and steel dust are, but I’m not ready to be a test subject either. You may have noticed the ugly looking box around my chop saw. It’s not only a catch basin for shaft ends, but is also used in conjunction with a shop vac to keep airborne dust to a minimum in my basement. I designed it to act as a mini-negative air system.

Most tool shops like Harbour Freight (or Princess Auto/Busy Bee Tools in Canada) have some type of inexpensive dust collector, and even a shop vac can do the trick. When purchasing a dust collection system, look out for CFM, or cubic feet per minute, which explains how much air/dust the system can collect as once. The more air that the system can pull through the filter the more dust it can pull out of the air. A simple cyclone system is about $100, but you can find mini 1HP systems (lots of power for a saw or small sander) for about $175 on sale or between $200-$250 full price.

Gripping Station

When it comes to gripping clubs, the best solution is a proper gripping station that will collect and recycle grip solvent and safely hold a club “square.” The nicest shop I ever worked in had foot-activated pneumatic clamps that automatically adjusted pressure, just like a tour van. Starting with solvent, it’s never good to run that stuff into a drain or have it sitting in an open container, especially with children or pets kicking around. My setup, although not perfect, is very effective at not wasting solvent and allowing me to get grips on in a timely fashion. The picture shows exactly how I recycle my solvent. Like I said, it’s not fancy, but it is very effective. This exact system from GolfMechanix is $185 before the cost of solvent or tape.

Graphite Shaft Puller

So you want to pull a graphite shaft? Like I mentioned in my last article, Avoid These 5 Club Building Disasters, there is a right way and a wrong a way to do it. Using a proper shaft extractor is necessary for graphite because of the fibers and the way the graphite sheets are wrapped. If you plan on doing a bit more than just the occasional shaft pull, I ALWAYS recommend using one with either a spring or hydraulic mechanism. Maltby makes a few really nice ones, as does GolfMechanix. I’ve had my Golf Mechanix shaft puller for more than 10 years now with no problems and hundreds of shafts pulled. The model in the photo retails for $350.

Loft-Lie Machine

Loft-lie machines are pricey, but just like a belt sander a good one is very much worth it. If you’re entrepreneurial, loft-lie machines can be a good little money maker, too, since the golf shops that have them can be few and far between, depending on where you live. Do good work on a few clubs for friends and word will spread. Believe me.

The cream of the crop loft-lie machines are digital. I wish I had one, but know that a well-machined loft-lie machine can be just as effective. Just like with the shaft puller, a great one can be had from Maltby and Golf Mechanix. On top of a loft-lie machine for irons, a separate loft-lie machine for putters is a really nice thing to have. Mine is from an older Wilson Staff unit dating back to when Kirk Currie was still making putters. It’s most effective with blade style putters, but can be used with most styles. Again, you don’t need to completely break the bank to have an effective shop with the right tools.

Don’t forget to make sure to get a good, non-maring bending bar tool, too. Bending marks are almost unavoidable for certain iron heads, but to make as few marks as possible a good bending bar is key.

A professional-quality loft/lie machine starts at around $550, but prices can get into the thousands. On top of that, a proper base usually add about $100-$200 to the cost. Putter machines are about $300 to start, but remember, bend a few putters for friends with great results and you will start getting phone calls.

Frequency Machine

This is a tool that certainly falls under the category of a luxury build shop item. My personal machine is a older model that was built and designed by Fujikura, which has a pneumatic pressure controlled clamping system to ensure consistent results. The age or model of the frequency machine has little impact on the reading that are put out (as long as it’s a quality, properly calibrated machine). The other specification to pay attention to is clamp length. You will get vastly different readings depending on the clamp length used, and if you’re using a computer-based formula your entire set could be off because of the clamp length.

Some newer machines have clamps that can be adjusted from 3-5 inches. I wouldn’t build a set of irons without it, but then again, club building was my livelihood and I’ve gotten used to the luxury. A frequency machine is by no means a necessary tool when it comes to doing home builds and repairs, as they start at about $550. A nice one from Maltby goes for $650, and a top-of-the-line model from GolfMechanix will set you back $750.

Air Compressor

An air compressor is a tool that falls under the category of “not just useful for a custom shop.” An air compressor has an abundance of uses including blowing on grips, cleaning out hosels and powering a plethora of pneumatic tools. I always charge mine up when building iron sets for use with my frequency machine, as well as making sure clubhead hosels are clean and ready to go for gluing. I selected mine based on three things:

- Size. This was important, because it needed to fit in my smaller shop.

- Volume. It needed have a tank big enough that it didn’t have to charge every time I used a tool. Also, pay attention to CFM (cubic feet per minute), which is how efficient the compressor is at filling the tanking and keeping up with demand.

- Noise. Most small compressors have a decibel rating. Try and find one that’s not too loud. Some are even advertised as being more quiet. It’s not always a big deal, especially if you’re working in a larger space, but can be key in a smaller shop.

A nice, simple compressor will go for around $150.

So what am I missing?

I realize that I haven’t even begun to cover cover all the small tools that can be very important when building clubs. In attempt to offer a complete list, I have compiled the items below.

- Bench ruler designed to measure golf clubs.

- Swing weight scale. Digital is best, but conventional is still very good.

- Digital scale that reads to +/-0.1 grams.

- Wire brushes for cleaning out hosels.

- Ram rod for removing old stuck tip weights and epoxy.

- Ferrules of all sizes, shims and tip weights.

- Sanding belts for prepping shafts (80 or 120 grit works well).

- SHARPIES! You can never have enough.

- Small pliers and clips.

- Acetone.

- Sand paper of varying grits.

- Gloves for using acetone. It can be nasty on the skin.

- Safety glasses. I can’t stress this enough.

- Calipers (digital are best, but analog can do the trick).

- Grip tape.

- Sharp hook knife and straight blade.

- Butane torch with extra fuel.

- Flash lights.

- Scissors

- Metal trash bin

Questions, concerns or comments? Let me know in the comments section below. I’ll do my best to answer all I can.

Opinion & Analysis

The 2 primary challenges golf equipment companies face

As the editor-in-chief of this website and an observer of the GolfWRX forums and other online golf equipment discourse for over a decade, I’m pretty well attuned to the grunts and grumbles of a significant portion of the golf equipment purchasing spectrum. And before you accuse me of lording above all in some digital ivory tower, I’d like to offer that I worked at golf courses (public and private) for years prior to picking up my pen, so I’m well-versed in the non-degenerate golf equipment consumers out there. I touched (green)grass (retail)!

Complaints about the ills of and related to the OEMs usually follow some version of: Product cycles are too short for real innovation, tour equipment isn’t the same as retail (which is largely not true, by the way), too much is invested in marketing and not enough in R&D, top staffer X hasn’t even put the new driver in play, so it’s obviously not superior to the previous generation, prices are too high, and on and on.

Without digging into the merits of any of these claims, which I believe are mostly red herrings, I’d like to bring into view of our rangefinder what I believe to be the two primary difficulties golf equipment companies face.

One: As Terry Koehler, back when he was the CEO of Ben Hogan, told me at the time of the Ft Worth irons launch, if you can’t regularly hit the golf ball in a coin-sized area in the middle of the face, there’s not a ton that iron technology can do for you. Now, this is less true now with respect to irons than when he said it, and is less and less true by degrees as the clubs get larger (utilities, fairways, hybrids, drivers), but there remains a great deal of golf equipment truth in that statement. Think about it — which is to say, in TL;DR fashion, get lessons from a qualified instructor who will teach you about the fundamentals of repeatable impact and how the golf swing works, not just offer band-aid fixes. If you can’t repeatably deliver the golf club to the golf ball in something resembling the manner it was designed for, how can you expect to be getting the most out of the club — put another way, the maximum value from your investment?

Similarly, game improvement equipment can only improve your game if you game it. In other words, get fit for the clubs you ought to be playing rather than filling the bag with the ones you wish you could hit or used to be able to hit. Of course, don’t do this if you don’t care about performance and just want to hit a forged blade while playing off an 18 handicap. That’s absolutely fine. There were plenty of members in clubs back in the day playing Hogan Apex or Mizuno MP-32 irons who had no business doing so from a ballstriking standpoint, but they enjoyed their look, feel, and complementary qualities to their Gatsby hats and cashmere sweaters. Do what brings you a measure of joy in this maddening game.

Now, the second issue. This is not a plea for non-conforming equipment; rather, it is a statement of fact. USGA/R&A limits on every facet of golf equipment are detrimental to golf equipment manufacturers. Sure, you know this, but do you think about it as it applies to almost every element of equipment? A 500cc driver would be inherently more forgiving than a 460cc, as one with a COR measurement in excess of 0.83. 50-inch shafts. Box grooves. And on and on.

Would fewer regulations be objectively bad for the game? Would this erode its soul? Fortunately, that’s beside the point of this exercise, which is merely to point out the facts. The fact, in this case, is that equipment restrictions and regulations are the slaughterbench of an abundance of innovation in the golf equipment space. Is this for the best? Well, now I’ve asked the question twice and might as well give a partial response, I guess my answer to that would be, “It depends on what type of golf you’re playing and who you’re playing it with.”

For my part, I don’t mind embarrassing myself with vintage blades and persimmons chasing after the quasi-spiritual elevation of a well-struck shot, but that’s just me. Plenty of folks don’t give a damn if their grooves are conforming. Plenty of folks think the folks in Liberty Corner ought to add a prison to the museum for such offences. And those are just a few of the considerations for the amateur game — which doesn’t get inside the gallery ropes of the pro game…

Different strokes in the game of golf, in my humble opinion.

Anyway, I believe equipment company engineers are genuinely trying to build better equipment year over year. The marketing departments are trying to find ways to make this equipment appeal to the broadest segment of the golf market possible. All of this against (1) the backdrop of — at least for now — firm product cycles. And golfers who, with their ~15 average handicap (men), for the most part, are not striping the golf ball like Tiger in his prime and seem to have less and less time year over year to practice and improve. (2) Regulations that massively restrict what they’re able to do…

That’s the landscape as I see it and the real headwinds for golf equipment companies. No doubt, there’s more I haven’t considered, but I think the previous is a better — and better faith — point of departure when formulating any serious commentary on the golf equipment world than some of the more cynical and conspiratorial takes I hear.

Agree? Disagree? Think I’m worthy of an Adam Hadwin-esque security guard tackle? Let me know in the comments.

@golfoncbs The infamous Adam Hadwin tackle ? #golf #fyp #canada #pgatour #adamhadwin ? Ghibli-style nostalgic waltz – MaSssuguMusic

Podcasts

Fore Love of Golf: Introducing a new club concept

Episode #16 brings us Cliff McKinney. Cliff is the founder of Old Charlie Golf Club, a new club, and concept, to be built in the Florida panhandle. The model is quite interesting and aims to make great, private golf more affordable. We hope you enjoy the show!

Opinion & Analysis

On Scottie Scheffler wondering ‘What’s the point of winning?’

Last week, I came across a reel from BBC Sport on Instagram featuring Scottie Scheffler speaking to the media ahead of The Open at Royal Portrush. In it, he shared that he often wonders what the point is of wanting to win tournaments so badly — especially when he knows, deep down, that it doesn’t lead to a truly fulfilling life.

View this post on Instagram

“Is it great to be able to win tournaments and to accomplish the things I have in the game of golf? Yeah, it brings tears to my eyes just to think about it because I’ve literally worked my entire life to be good at this sport,” Scheffler said. “To have that kind of sense of accomplishment, I think, is a pretty cool feeling. To get to live out your dreams is very special, but at the end of the day, I’m not out here to inspire the next generation of golfers. I’m not out here to inspire someone to be the best player in the world, because what’s the point?”

Ironically — or perhaps perfectly — he went on to win the claret jug.

That question — what’s the point of winning? — cuts straight to the heart of the human journey.

As someone who’s spent over two decades in the trenches of professional golf, and in deep study of the mental, emotional, and spiritual dimensions of the game, I see Scottie’s inner conflict as a sign of soul evolution in motion.

I came to golf late. I wasn’t a junior standout or college All-American. At 27, I left a steady corporate job to see if I could be on the PGA Tour starting as a 14-handicap, average-length hitter. Over the years, my journey has been defined less by trophies and more by the relentless effort to navigate the deeply inequitable and gated system of professional golf — an effort that ultimately turned inward and helped me evolve as both a golfer and a person.

One perspective that helped me make sense of this inner dissonance around competition and our culture’s tendency to overvalue winning is the idea of soul evolution.

The University of Virginia’s Division of Perceptual Studies has done extensive research on reincarnation, and Netflix’s Surviving Death (Episode 6) explores the topic, too. Whether you take it literally or metaphorically, the idea that we’re on a long arc of growth — from beginner to sage elder — offers a profound perspective.

If you accept the premise literally, then terms like “young soul” and “old soul” start to hold meaning. However, even if we set the word “soul” aside, it’s easy to see that different levels of life experience produce different worldviews.

Newer souls — or people in earlier stages of their development — may be curious and kind but still lack discernment or depth. There is a naivety, and they don’t yet question as deeply, tending to see things in black and white, partly because certainty feels safer than confronting the unknown.

As we gain more experience, we begin to experiment. We test limits. We chase extreme external goals — sometimes at the expense of health, relationships, or inner peace — still operating from hunger, ambition, and the fragility of the ego.

It’s a necessary stage, but often a turbulent and unfulfilling one.

David Duval fell off the map after reaching World No. 1. Bubba Watson had his own “Is this it?” moment with his caddie, Ted Scott, after winning the Masters.

In Aaron Rodgers: Enigma, reflecting on his 2011 Super Bowl win, Rodgers said:

“Now I’ve accomplished the only thing that I really, really wanted to do in my life. Now what? I was like, ‘Did I aim at the wrong thing? Did I spend too much time thinking about stuff that ultimately doesn’t give you true happiness?’”

Jim Carrey once said, “I think everybody should get rich and famous and do everything they ever dreamed of so they can see that it’s not the answer.”

Eventually, though, something shifts.

We begin to see in shades of gray. Winning, dominating, accumulating—these pursuits lose their shine. The rewards feel more fleeting. Living in a constant state of fight-or-flight makes us feel alive, yes, but not happy and joyful.

Compassion begins to replace ambition. Love, presence, and gratitude become more fulfilling than status, profits, or trophies. We crave balance over burnout. Collaboration over competition. Meaning over metrics.

Interestingly, if we zoom out, we can apply this same model to nations and cultures. Countries, like people, have a collective “soul stage” made up of the individuals within them.

Take the United States, for example. I’d place it as a mid-level soul: highly competitive and deeply driven, but still learning emotional maturity. Still uncomfortable with nuance. Still believing that more is always better. Despite its global wins, the U.S. currently ranks just 23rd in happiness (as of 2025). You might liken it to a gifted teenager—bold, eager, and ambitious, but angsty and still figuring out how to live well and in balance. As much as a parent wants to protect their child, sometimes the child has to make their own mistakes to truly grow.

So when Scottie Scheffler wonders what the point of winning is, I don’t see someone losing strength.

I see someone evolving.

He’s beginning to look beyond the leaderboard. Beyond metrics of success that carry a lower vibration. And yet, in a poetic twist, Scheffler did go on to win The Open. But that only reinforces the point: even at the pinnacle, the question remains. And if more of us in the golf and sports world — and in U.S. culture at large — started asking similar questions, we might discover that the more meaningful trophy isn’t about accumulating or beating others at all costs.

It’s about awakening and evolving to something more than winning could ever promise.

KENS CUSTOM CLUBS. PXG DEALER

Apr 30, 2019 at 6:04 pm

Chop saw is a no no, to much dust a good wet saw with proper blade and also a complete bench collection system, throw in a good launch monitor and 25 years experience also club fitting schools and club building schools and you might be getting close also a moment of inertia machine to ho beyond swingweight and make every iron feel the same could go on with more list never ends if you want to keep up with technology.

geohogan

Mar 4, 2019 at 1:19 pm

Please, where is the fire extinguisher?

Grinding sparks ignited on the bench after I finished grinding.

I almost lost my home to a fire on my work bench.

There is wood and flammable chemicals. Have to have a working fire extinguisher and know how to use it. cheers

Tom D

Oct 17, 2016 at 3:22 pm

Heck, I’d love to get a loft/lie machine and I’m closer to 60 that to 16!

Andrew Nielsen

Oct 9, 2016 at 10:30 pm

Great article and appreciate the tip on the Gryphon Mitre Saw. Been looking for a small chop saw just for shafts and the Gryphon is perfect. Any recommendations on Bench top drill presses?

Skip VanB

Oct 7, 2016 at 3:19 pm

Ryan,

Great fun article! That’s a nice shop you have. Where did the base for your work bench, the one with your vice come from?

Ryan Barath

Oct 7, 2016 at 9:48 pm

Hi Skip,

I’m gonna be straight up, I am a very lucky guy to not only be married to a great lady, but to also have a very talented brother-in-law. He’s is not only a welder, but also a great designer of all things metal. This base was completely custom built to the space that I had and specs that I gave him ( although I installed the vice on my own after the bench was built )

But for most, there are a bunch of bench kit system that very easily allow you to build to your spec at a very reasonable cost. You just need to buy the metal or plastic fibre brackets and then have the base pieces cut to length.

Really hope this helps.

Ryan

alan

Oct 6, 2016 at 7:53 am

nice article thanks. i tinker around in my garage and get by.

my wife is canadian. we head up to muskoka usually once a year. when we are on the 403 bridge i look over at hamilton and wonder who would wanna live in hamilton. now i know!

Wesley

Oct 5, 2016 at 10:57 pm

Great article Ryan. I have all these tools but some are less costly like club scout. Folks don’t forget there are plenty of places like harbor freight to get tools that will perform same function for significantly less cost than golf specific suppliers.

Ryan Barath

Oct 6, 2016 at 1:08 am

Exactly!

I really tried to stress that you can stretch your dollar by purchasing either used or more cost effective options with certain tools. This is also very effective since most people are only going to go as far as using the tools irregularly and because of that lighter duty machines can be just as effective.

Travis S

Oct 5, 2016 at 10:55 pm

If you had to guess how much would everything cost for this complete setup? Just the necessities tools and machines not the extra parts like ferrules, tape and etc?

Ryan Barath

Oct 6, 2016 at 1:10 am

from new you’re looking at probably close to $5000 but if going used like I did and if you are willing to invest some time in building a few things yourself you can do it for less than half.

Travis S

Oct 5, 2016 at 10:52 pm

What a great story I just started tinkering this year and installed a vice. I would kill for all that and appreciate your enthusiasm and modest cost effective setup. Keep up the good work!

Grizz01

Oct 5, 2016 at 10:17 pm

If you are building your own clubs and tinkering around. You don’t need all that crap.

KK

Oct 5, 2016 at 7:02 pm

Missing hotmelt setup. Otherwise absolutely fantastic.

Ryan Barath

Oct 5, 2016 at 9:25 pm

100%

I have used them many times before, but just like with the chop saw, I don’t want to buy a cheap one at the moment and I’m waiting to buy the champ model used on tour vans.

DJ

Oct 5, 2016 at 4:15 pm

Regarding dust collection systems. A really good club fitter I went too never had a vacuum system to control dust, specifically when cutting graphite shafts. He had to quit his business since all those years of breathing graphite led to him losing 40% lung capacity. Reason enough to invest in a high quality system if you are going to make this more than a hobby.

Ryan Barath

Oct 5, 2016 at 8:57 pm

Exactly!

Breathing in any sort of small particles for a long period of time is never good. Its the exact reason I do all of my finishing work and grind work in a proper metal shop, and with a dust mask.

John G

Oct 5, 2016 at 3:15 pm

Nice article for beginner but we know that when one starts repairing/rebuilding/building clubs from everywhere, tools and parts really-really add up fast.

When I started many years ago, most all my tools came from Mitchell and this or that special tool or part is always on going.

Steven

Oct 5, 2016 at 2:25 pm

Wow, that is an impressive setup. I don’t know if I want to build or alter clubs, but looking at the setup makes me want to try.

Blade Junkie

Oct 5, 2016 at 1:02 pm

You don’t know how lucky you are in the USA having big houses, basements and huge garages to put all this stuff. Many of us in the UK are making do with a 6′ x 3′ garden shed LOL.

Jason Thompson

Oct 5, 2016 at 10:58 am

I’m curious what large scale workshops you have built? I know the guys who did Modern Golf’s and you weren’t even employed there.

NFG

Oct 5, 2016 at 10:49 am

I want to be like this guy, sweet set up!! My work shop is small but I can do what I need to do.

alexdub

Oct 5, 2016 at 10:43 am

Great write-up! This is one of the better features from GolfWRX in a while. Who doesn’t love repair shop man caves>?

Ryan Barath

Oct 5, 2016 at 8:59 pm

Thanks!

This really was a subject I wanted to cover and share. I’m glad you like it.

Christopher

Oct 5, 2016 at 10:20 am

Can you share your plans you used for that bench ruler. I like that setup!

Ryan Barath

Oct 5, 2016 at 9:04 pm

Here’s the Link to my GolfWRX post from last year where I posted exactly how I made it.

http://www.golfwrx.com/forums/topic/1197824-my-very-easy-diy-bench-ruler-plans-why-spend-when-you-can-spend-and-be-accurate-home-shop-pics-incd/page__p__11807904__hl__+build%20+bench%20+ruler#entry11807904

RAT

Oct 5, 2016 at 10:02 am

Interesting , gone from just a little to making it a vocation. Start up – pick 3 of the most important, forget the small hand tools and etc.

Jim

Oct 5, 2016 at 9:59 am

Drill Press is a must for accurate, straight/tight hosel bores.

Tom

Oct 5, 2016 at 12:04 pm

amen to that

Tom

Oct 5, 2016 at 9:05 am

Great hobby to get involved in if your a serious golfer. I do it so that I can buy inexpensive sets of irons. Take measurements, make adjustments for junior player just starting he game.

David W.

Oct 5, 2016 at 8:23 am

Good stuff! Not going to build anything myself, but a great read.

Charlie

Oct 5, 2016 at 7:54 am

Were you seeing just how much you could bend a Mizuno MP T11 wedge before it snaps?

Ryan Barath

Oct 5, 2016 at 9:08 pm

I wasn’t sure someone would catch that or not.

It was a Mizuno wedge I bent completely flat: 0 LIE, 0 LOFT. I thought it was going to break when i did it but it just kept going. I actually have two, 1 is a paper weight (pictured) and the other is an assembled club that’s around 14″ long. It looks hilarious and is fun to try and hit a ball with.