Equipment

GolfWRX Vault: Avoid these 5 club building disasters

It’s never too late to go back to basics, especially when it comes to club building.

Even with modern new club release cycles the do’s and don’ts of building clubs haven’t changed much in the last few decades except for clubs with adapter sleeves and greater amounts of multi-materials incorporated into the design.

With that in mind its time to revisit an article from the GolfWRX Vault from June 2016.

——————

I’ve been fitting and building golf clubs for more than 15 years, and in that time I’ve seen a lot of really poor workmanship—stuff that would make most GolfWRXers cringe. But like anyone who ever did anything new, I didn’t start being naturally good at putting together clubs. It took a lot of time, ruined components, and trial and error to get where I am today.

I believe my attention to detail now stems from the fact that my dad was a machinist by trade, and anytime we ever worked on something together his attitude was to take your time and do it right the first time. My dad’s approach always had an impact on me, because I feel that if you do something right — even when it takes a bit longer — the job is not only more satisfying but also makes things work better and last longer.

The goal with this article is to help WRXers avoid the most common mistakes and assumptions in club building that lead to broken or ruined clubs, as well as real danger.

Over-prepping a graphite shaft

The shaft on the left has been prepped properly. The one of the right, which has noticeable taper, shows signs that layers of graphite have been removed.

This happens far more than it should, and can ruin an expensive new shaft purchase. To prepare a shaft properly for installation, you only need to remove enough of the paint to make sure that the epoxy adheres to the graphite. This is also true for the inside of the hosel.

Be careful to remove residual epoxy, dirt or rust (common with forged carbon steel club heads that have been sitting around for a while), or some type or solvent like the one used to put on grips, as it can cause of bond to break down very quickly. A proper reaming tool, a wire brush and some compressed air (either a small can or a large air compressor) can make cleaning simple, and prevent a golf club from falling apart.

UPDATE: Over prepping specifically applies to shafts that are designed to go into parallel heads and is especially important for 335 shafts with less material at the tip going into drivers and fairway woods. For information on how to properly taper a shaft to go into a tapered head, check out the video below:

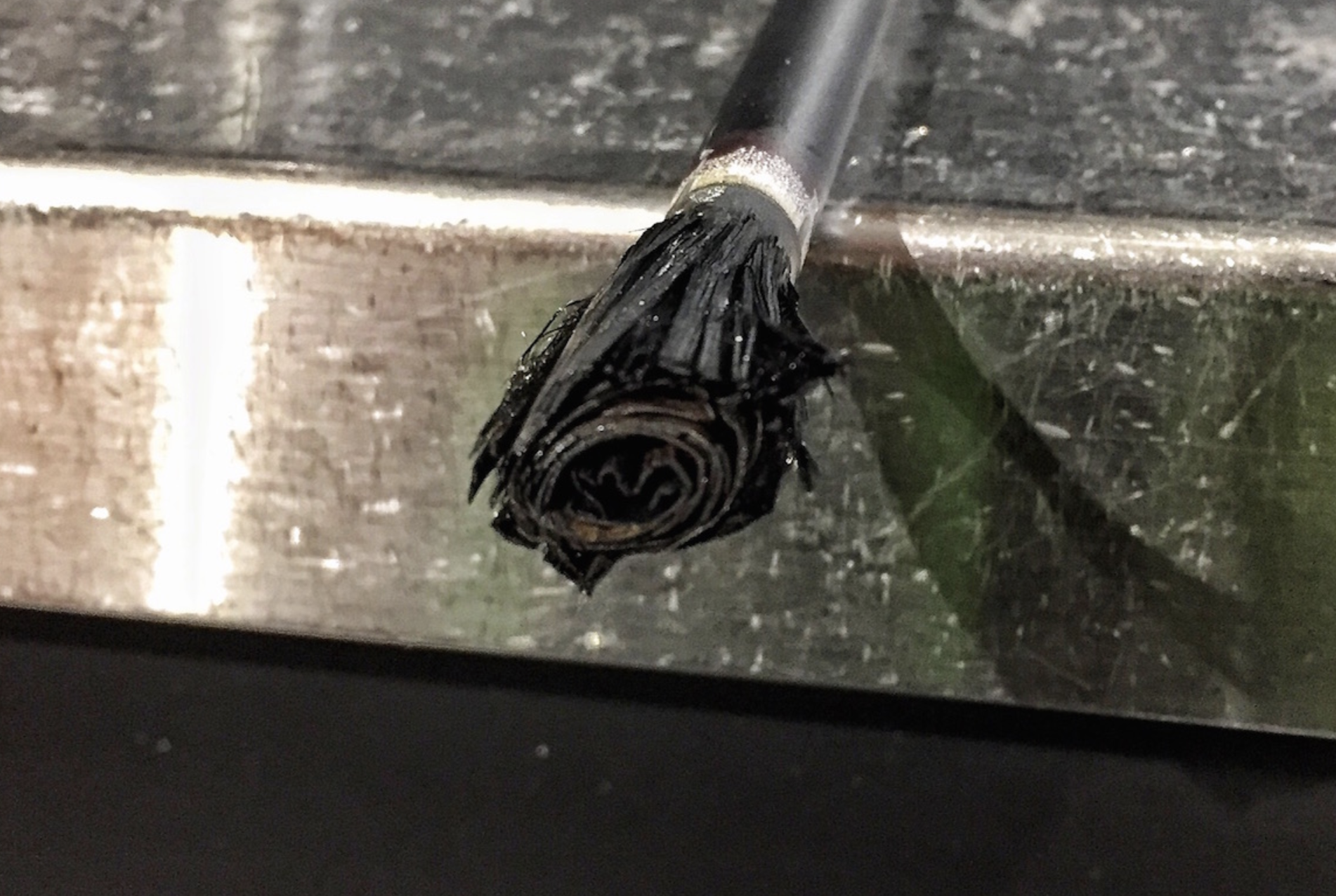

Overheating a Shaft When Pulling it

This is what happens to a graphite shaft when overheated, and the resin holding the graphite sheets together breaks down. It’s not always as noticeable, but if the shaft starts to fray it means the bonds have been compromised and it’s more likely to fail.

Overheating a shaft when pulling it is another common mistake that can result in ruining a golf shaft. It also highly increases the chance of breakage. There are quite a few methods I’ve learned over the years to remove a shaft from a club head, from heat guns to large propane torches, but personally I find that using a small butane torch with a regulator for graphite offers the best results. It allows a club builder to easily control and focus the heat only where it’s needed. Bigger torches are fine for iron heads, as long as you don’t damage any plastic badges in the cavity or materials in slots around the head.

One of the best advances in club technology has been the invention and mass adoption of adjustable hosels. They not only help golfers adjust the loft, lie and face angle of club heads, but have also greatly decreased the need to pull shafts. So as long as a golfer is staying with the same metal wood manufacturer, they can usually test several different clubs heads with the same shaft, or vice versa — several different shafts with the same clubhead.

That being said, one of the most important tools that any hobbyist club builder should have or have access to is a high-quality shaft puller. It’s a necessary tool for anyone who wants to do repairs and helps prevent damage to a shaft while pulling it. The more linear pressure that can be applied to the clubhead, and the less heat used to break down the epoxy, the better. It makes sure both the shaft and the head are reusable in the future. For steel shafts, you can use a bit more heat, and twisting isn’t a problem. Again, with increased heat, be careful not to damage any of the badging, or permanently discolor an iron head.

Botching a Grip Installation

Using calipers and two-sided tape, you can replicate the taper of shafts to makes every grip feel exactly the same size in your set.

This one seems simple, but when really getting down to professional level detail, it is quite important. We ALL have a preference and different opinion of what feels good in a golf grip, as well as different sensitivities. For example, we all have the ability to figure out what apple is bigger, even if blindfolded because over time we all develop brain function to understand shapes and sizes. This also applies to grips. If you use the same grips on your 13 clubs, you could potentially have 4-5 different final sizes depending on how many different types of shafts you use, because many shafts have different butt diameters.

Some shafts have larger butt diameters, while others taper faster than others. That’s why it’s very important to own a quality set of vernier calipers, and know how to properly use them. It’s also the same for putters, since many putter shafts are smaller in diameter. I have lost count of how many times I’ve had people bring me, putters, where the bottom half of the grip is twisting and turning because the installer never paid attention to the interior diameter of the grip, the exterior diameter of the shaft, and how it changed from top to bottom.

Using epoxy that’s doomed to fail

I’m a bit of a physics nerd and garage engineer, so this is one of those topics that goes beyond just the physical aspects of club building and into the realm of chemistry.

Here comes my nerd-out moment: In the simplest of explanations for a 0.335-inch driver hosel with an insertion depth of 1.25 inches, the amount of calculated surface area the epoxy can bond between the shaft and the head using the internal dimensions of the head is 1.49 square inches. That’s not a whole lot of area when you consider the centrifugal force being applied to a driver head traveling at 100 mph, and then the forces of torque that also come into play when a shot is struck.

In a PERFECT world, almost zero torque is applied to a shaft when a shot is hit on the center of gravity (CG) of the club head, perfectly aligned with the center mass of the ball, while traveling in the intended direction. This is vectors 101 of physics. Unfortunately, almost every single shot is NOT hit like that, and this is where the epoxy bond is put under the most amount of stress. Lap shear strength of epoxy goes beyond me, but it proves that building a golf club is not just cut and glue after all.

Note: For those of you curious, the most popular epoxies are rated for 4500 psi.

As far are actually working with epoxy, first things first. Always check to see if the epoxy has a best-before date (yep, just like milk). Also, never store epoxy in direct sunlight. If you are using epoxy from a tube in a dispensing gun, you are using what is an almost foolproof method. Plunge out the necessary amount, mix for about a minute (mix! don’t whip), and remember, the less air that gets into the epoxy the better. If air gets in and the epoxy cures with bubbles in it, then you end up with a club that will often “creak.”

For those using two parts in larger bottles, the best way to ensure proper ratios is to pay attention to the weight ratio rather than volume. This isn’t arts and crafts; it’s chemistry, so by using the weight to calculate the ratio you will get the right amount of each part every time, and help decrease the risk of failure down the road. If you have mixed a larger batch and plan on building quite a few clubs at a time, you really have to pay attention to the consistency and viscosity as time goes on. You don’t want to glue a club head with epoxy that has started to set.

Turning an Extension into a Shank

This is one of those subjects I don’t even like to talk about. I very much dislike using extensions when building clubs, especially clubs with graphite shafts. Going back to my “do-it-right-the-first-time” mentality, extensions are a Band-Aid fix to a problem that requires surgery. They also counter-balance the club, and by their very nature create a weak point because of the small wall thickness at the butt end of a shaft. The only clubs I don’t mind extending on a regular basis are putters since they are never put under the same level of stress as a club being swung at full speed. I also never extend a club more than 1 inch, because I have been witness to horror stories of clubs that have been overextended that not only break but rip through the grip and cut people’s hands very badly.

If you are going to extend a club, it’s important to make sure the fit is very snug and doesn’t cause the extension to lean in any direction. It’s also best to have the epoxied extension cure with the club on its side to avoid an excess epoxy from running down the shaft and breaking off and causing a rattle.

Equipment

BK’s Breakdowns: Cameron Young’s winning WITB, 2025 Wyndham Championship

Cameron Young’s WITB from his win at the 2025 Wyndham Championship. Cameron is a Titleist staff player but his bag is definitely filled with some unique clubs. Here are the clubs he used to secure his first PGA Tour win!

Driver: Titleist GT2 (9 degrees, A1 SureFit setting)

Shaft: Mitsubishi Tensei 1K Pro Orange 70 TX

3-wood: Titleist GT3 (15 degrees)

Shaft: Mitsubishi Tensei 1K White 80 TX

Hybrid: Titleist GT2 (21 degrees)

Shaft: Fujikura Ventus HB Black VeloCore+ 10 X

Irons: Titleist T200 (4), Titleist T100 (5), Titleist 631.CY Prototype (6-9)

Shafts: True Temper Dynamic Gold X7 (4-9)

Wedges: Titleist Vokey Design SM10 (48-10F, 52-12F, 56-14F @57), WedgeWorks (60-K* @62)

Shafts: True Temper Dynamic Gold X7

Putter: Scotty Cameron Phantom 9.5 Tour Prototype

Grips: Golf Pride Tour Velvet Cord

Ball: Titleist Pro V1x Prototype

Whats in the Bag

Peter Malnati WITB 2025 (August)

- Peter Malnati what’s in the bag accurate as of the Wyndham Championship. More photos from the event here.

Driver: Titleist GT3 (10 degrees, C2 SureFit setting)

Shaft: Project X Denali Blue 60 TX

3-wood: Titleist GT3 (15 degrees, A1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 7 X

7-wood: Titleist GT2 (21 degrees, D1 SureFit setting)

Shaft: Fujikura Ventus TR Blue 8 X

Irons: Titleist T150 (4, 5), Titleist T100 (6-9)

Shafts: True Temper AMT Tour White X100

Wedges: Titleist Vokey Design SM10 (48-10F @47, 52-12F, 56-08M @57, 60-04T @62)

Shafts: True Temper Dynamic Gold Tour Issue S400

Putter: Scotty Cameron Studio Style Fastback 1.5 Tour Prototype

Grips: Golf Pride Tour Velvet

Ball: Titleist Pro V1x Yellow

Equipment

GolfWRX Members Choice presented by 2nd Swing: Best driver of 2025

We’re proud to once again partner with 2nd Swing Golf to bring you GolfWRX Members Choice 2025! 2nd Swing has more than 150,000 new and pre-swung golf clubs available in six store locations and online. Check them out here.

What is the best driver in 2025? At GolfWRX, we take great pride in our online community and the cumulative knowledge and experience of our members. When it comes to the best driver of 2025, we want to know what our forum faithful think.

Since our founding in 2005, the bedrock of GolfWRX.com has been the community of passionate and knowledgeable golfers in our forums, and we put endless trust in the opinions of our GolfWRX members — the most knowledgeable community of golfers on the internet. No other group of golfers in the world tests golf clubs as frequently or as extensively, nor is armed with such in-depth information about the latest technology.

Below are the results of GolfWRX member voting for the 2025 best driver, along with the vote percentage for each club.

Best driver of 2025: The top 5

5. Callaway Elyte Triple Diamond: 6.02%

Callaway’s pitch: “For golfers looking for a fast, forgiving, yet workable driver, the Elyte Triple Diamond features a tour-inspired shape and is the preferred model by most Callaway tour players.”

You can read what other golfers are saying about the driver in the GolfWRX forums, and see our launch piece here. Shop the Callaway Elyte Triple Diamond here.

4. Ping G440 Max: 6.86%

Ping’s pitch: “The most forgiving G440 model, MAX has a hotter face to generate speed and distance, and a lighter overall system weight with a longer shaft (46″) for faster clubhead speed, higher launch and longer carries. The Free Hosel and Carbonfly Wrap crown save weight to create our lowest CG ever and increase forgiveness while contributing to a more muted, pleasing sound.”

You can read what other golfers are saying about the driver in the GolfWRX forums, and see our launch piece here. Shop the Ping G440 Max here.

3. Ping G440 LST: 9.53%

Ping’s pitch: “LST is an especially good fit for faster swings, offering less spin and more control with a penetrating trajectory. A hotter face, lighter overall system weight and longer shaft (46″) deliver more speed and distance while maintaining tight dispersion.”

@phizzy30: “Not a fan of Ping drivers in general, but 440 LST takes the cake. It’s super forgiving across the face for a low spin head, looks and sounds good and the ability to make it play neutral or slightly fade biased through the hosel settings is very appealing.”

You can read what other golfers are saying about the driver in the GolfWRX forums, and see our launch piece here. Shop the Ping G440 LST here.

2. Titleist GT3: 16.55%

Titleist’s pitch: “The GT3 Driver offers Titleist’s boldest combination of power and personalization through adjustable performance. Dial in the CG Track to your frequent contact location to make your biggest drives even bigger while taking total control over flight and shaping.”

@mrmikeac: “I’ve been Anti-Titleist for years and years and years (outside of Vokey, of course). With that being said, HOLY BEGEEZUS the GT3 driver is an absolute NUCLEAR MONSTER! This thing blew my G430 10K Max out of the water in every single category. Forgiveness is the biggest thing that stands out of me, the 3 model has always been one of the less forgiving models in the past but this GT3 can take bad shot after bad shot and still end up in the fairway, I think a ton of that has to do with the adjustability, it’s actually effective. Feel and sound is perfect, that solid crack is so addicting to hear and when you hit it out the screws this thing can absolutely bomb it. Titleist, I’m sorry for doubting you. You have converted me.”

You can read what other golfers are saying about the driver in the GolfWRX forums, and see our launch piece here. Shop the Titleist GT3 here.

1. Titleist GT2: 22.91%

Titleist’s pitch: “Delivering impressive distance from any impact point, the Titleist GT2 Driver extracts maximum performance through a forgiving design. Get the stability and added confidence of a high-MOI driver without sacrificing speed.”

@DTorres: “The Titleist GT2 has proven to be the best driver of the year. Packaged in a classic profile, GT2 perfectly balances performance and forgiveness while consistently being a high performer across all categories.”

You can read what other golfers are saying about the driver in the GolfWRX forums, and see our launch piece here. Shop the Titleist GT2 here.

Other drivers receiving >2% of the vote

| Driver | Vote percentage (%) |

|---|---|

| Cobra DS Adapt Max K | 4.85% |

| Ping G430 Max 10K | 3.85% |

| Callaway Elyte Triple Diamond | 3.68% |

| TaylorMade Qi35 | 3.51% |

| Callaway Elyte | 3.18% |

| Cobra DS Adapt X | 2.34% |

| Cobra DS Adapt LS | 2.17% |

| TaylorMade Qi35 LS | 2.17% |

View this post on Instagram

DukeOfChinoHills

Apr 30, 2021 at 3:24 pm

#6. Using lead tape to counter-balance a shaft by placing it under a grip.

Jon

Apr 1, 2020 at 12:15 am

You’ve not mentioned the formula of depth ratio to extension length re extending any club. In my opinion one of the major mistakes that are made by people doing these improvements to their gear in the home work space/garage.

Scott

Apr 3, 2020 at 9:10 am

Jon, huh? Where else would you make improvements at home?

Euan Hardman

Mar 31, 2020 at 12:08 pm

I suppose that extending graphite shafts with off cuts from old shafts and then using superglue to fix them isn’t really approved?

Shame, I’ve done it several times for short extensions without any breakages……..so far!